IC Auto Handler

TI-H220

TI-H220 is an IC test handler that has been raised by semiconductor manufacturers for many years and knows everything about semiconductors. The system has a reputation for low impact, low noise, and ease of use, as well as high positional accuracy cultivated through our image inspection system. The system offers reliable handling at the final inspection process in semiconductor manufacturing.

Features

The TI-H220 is a tray-to-tray type IC Auto Handler that automatically transfers various types of ICs (QFN/LGA/CSP/QFP, etc.) stored in a supply tray, conducts electrical characteristics tests using a tester connected to the system, and classifies the ICs into good and bad trays based on the test results.

Despite its compact body, which is among the smallest in the industry, the robust design and image recognition technology enable high-precision handling. We meet the diverse needs of our customers, such as for small packaged products.

The TI-H220 contributes to yield improvement.

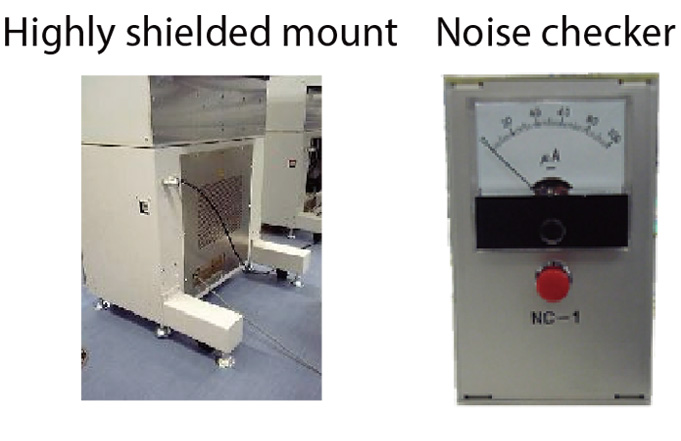

Thorough noise reduction design

Thorough noise reduction measures are taken from the housing and mechanism design stage, including the use of noise insulation materials and special crimped structures. This makes it possible to use the system in the selection process of devices that are particularly sensitive to electrical characteristics, such analog high-frequency devices.

Industry’s smallest compact body

The compact body is easy to move with a footprint of 0.86m² and a weight of 350kg. It contributes to improved productivity per unit area and flexibly responds to the installation environment limitation.

Detailed customization is available

Specifications

| Applicable device | BGA, CSP, QFN, QFP, SOP, etc | |

|---|---|---|

| Applicable package | □2mm~40mm ※Contact us for □2mm or below. | |

| Applicable tray | EIAJ、JEDEC (W135.8mm x D315.8mm), other trays (optional) | |

| No. of classification | 3 as standard (max. 15) | |

| No. of max test units | MAX. 2DUT | |

| Index time | 0.5 ~ 0.8 sec (Excluding convey time) | |

| Throughput | 2,100 units/hr (Excluding tray exchange time) | |

| Product exchange | Exchange time: 3min (including fixture & parameter exchange) | |

| User inferface | 12inch TFT color LCD touch panel | |

| Utilities | AC100V、15A、50/60Hz | |

| Max 0.4 ~ 0.7Mpa, 20Nl/min. dry air | ||

| Usage environment | Normal temperature, high temperature: ~ 125 degree C (optional) ※High temperature is only available for 1 DUT. Not available if “recognition” is selected. | |

| External dimensions | W832mm x D1,038mm x H1,380mm | |

| W832mm x D1,088mm x H1,380mm (optional) | ||

| Weight | 350 ~ 360kg | |