Automated X-ray Inspection System

TI-X500s / TI-X500i

The TI-X500s inspection system has an automated inspection function with high levels of accuracy, repeatability and reproducibility, as well as defect analysis function. The system is widely adopted in the SMT component placement processes and semiconductor manufacturing processes.

Features

TI-X500s is an X-ray inspection system that supports high-speed and high-definition 3D CT, vertical and oblique imaging and inspection function. The system supports automated inspection and defect analysis of C4 solder bumps and LTH internal plating filling conditions. It contributes to quality improvement not only in SMT component placement processes but also in semiconductor manufacturing processes.

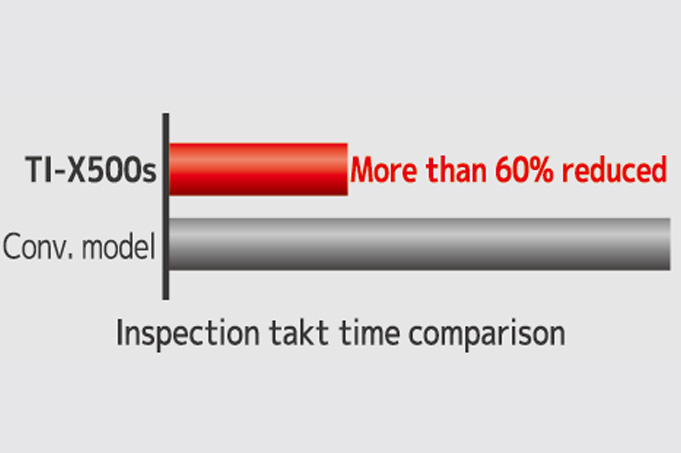

Offers high-speed throughput with new mechanism

The system is equipped with a high-speed, high-sensitivity FPD and a new mechanism, realizing a CT imaging time of less than 1/3 of conventional systems. CT imaging is completed in less than 8 seconds for one FOV when the number of imaging projections is 16*.

*The number of imaging projections and resolution vary depending on the condition of the object to be inspected.

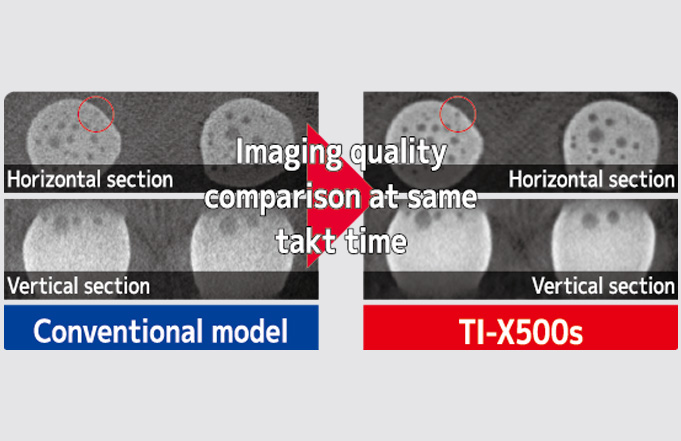

Offers higher image quality with proprietary technology and high-performance hardware

Mechanical precision has been greatly improved by increasing the rigidity of the frame and parallel drive control. In addition, the combination of proprietary image correction technology and a high-speed, high-sensitivity FPD has realized high-resolution imaging of 0.33µm at the finest (0.58µm for in-line machines). It can produce clear images capable of detecting minute defects.

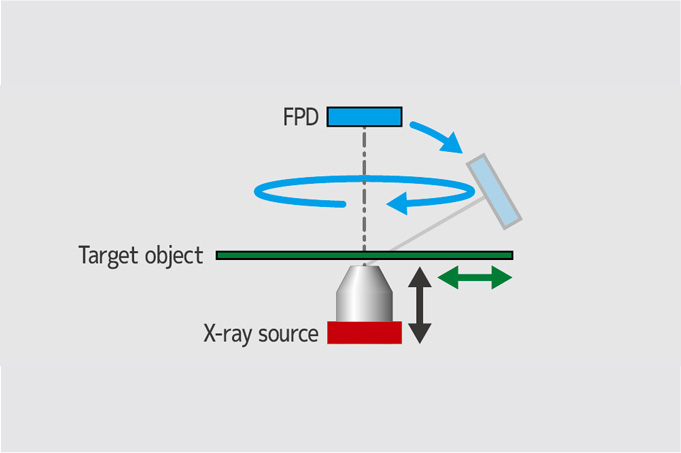

Covers vertical, oblique, and CT imaging with simple structure

The X-ray detector can be tilted at any angle from 0 to 60 degrees for imaging. This allows a single X-ray detector to be used for all imaging methods: vertical, oblique, and CT. The single X-ray detector also has the advantage of easy maintenance.

TI-X500i is available for in-line operation

The TI-X500i is equipped with a conveyor system capable of efficiently inspecting all PCBAs and high-density boards. We also have experience in substrate transfer and inspection using conveying trays.

Specifications

| Model | TI-X500s | TI-X500i |

|---|---|---|

| Inspectable board size | Dimensions: Max. W510 x L370mm *W515 x L610mm when carbon plate jig is used. Thickness: Max. 3mm, Weight: Max.2kg | Dimentions: Max. W350 x L350mm Thickness: Max. 3mm, Weight: Max.2kg |

| Board top/bottom clearance | Top: 50mm, Bottom:40mm | Top: 50mm, Bottom:30mm |

| Inspection item | 2D: Component inspection and solder bump inspection using transmission image 3D: Solder bump (BGA & C4) inspection and planting-filled TH inspection using CT image | |

| X-ray source | Open tube micro focus Tube voltage: 20~160kV Tube current: 0~200µA Max resolution: 1µm | |

| Detector | Sensor type: 3M pixels | |

| Oblique capturing angle | 0~60° | |

| Geometric magnification | Max. x900 | |

| Image magnification ratio | Vertical: Max. x225 Oblique capturing angle 60°: Max. x112 | Vertical: Max. x100 Oblique capturing angle 60°: Max. x50 |

| Image resolution | Vertical: Max. 0.33µm Oblique capturing angle 60°: Max.0.67µm | Vertical: Max. 0.75µm Oblique capturing angle 60°: Max.1.5µm |

| X-ray leakage dose | 0.5μSV/h or less | |

| External dimensions | W1,680mm × D1,990mm × H1,940mm | W1,680mm × D1,990mm × H1,940mm |

| Weight | 3,700kg | 4,000kg |

| Power supply voltage | Three-phase AC200-240V, 3kVA | |